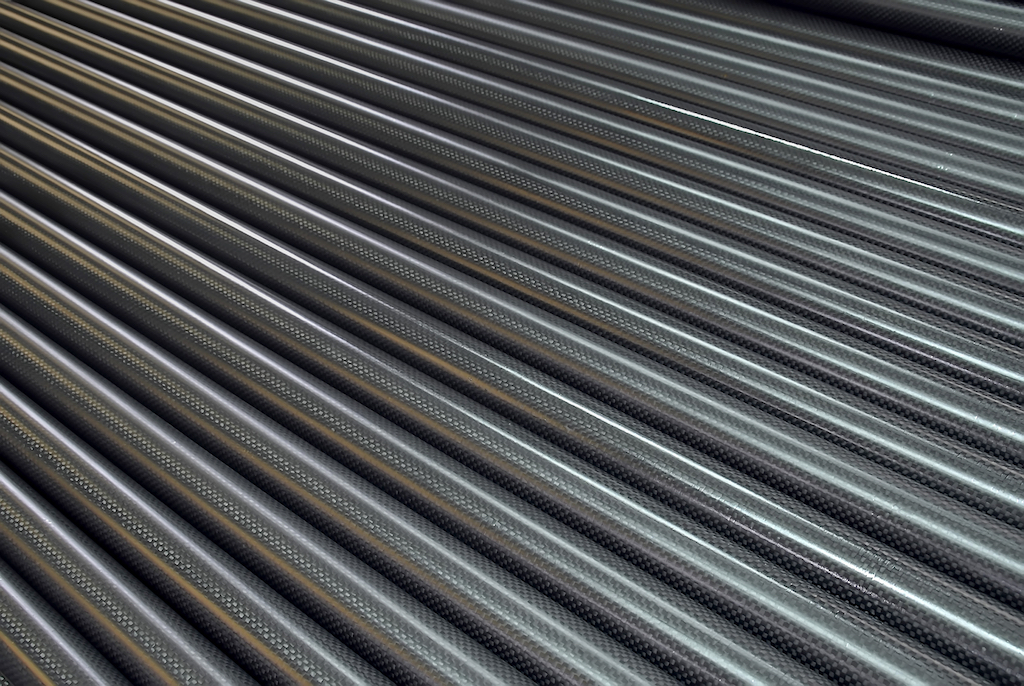

Hey there, gearheads and engineering enthusiasts! Are you on the hunt for the best carbon fiber shafts to elevate your projects? Whether you're building a drone, upgrading your RC car, or designing custom golf clubs, carbon fiber shafts are game-changers in the world of performance materials. These lightweight yet ultra-strong components are revolutionizing industries, and today, we're diving deep into what makes them the top choice for engineers, hobbyists, and professionals alike. So buckle up, because this ride is going to be packed with insights, tips, and recommendations!

Carbon fiber shafts are no longer just a niche product for aerospace and racing enthusiasts. These days, they're everywhere—from high-performance bicycles to industrial machinery. But with so many options out there, how do you know which ones are worth your time and money? We’ve got you covered. This guide will break down everything you need to know about the best carbon fiber shafts, including their benefits, applications, and where to find them.

Before we dive into the nitty-gritty, let’s set the stage. Carbon fiber is known for its incredible strength-to-weight ratio, corrosion resistance, and thermal stability. These properties make it an ideal material for applications where performance and reliability are critical. But not all carbon fiber shafts are created equal. In this article, we’ll explore what sets the best ones apart, so you can make an informed decision without breaking the bank. Ready? Let’s get started!

Read also:Celine Dions Health Battle How Shes Fighting Back And Preparing For Surgery

What Makes Carbon Fiber Shafts So Special?

Alright, let’s kick things off by talking about why carbon fiber shafts are such a big deal. If you’re new to the world of advanced materials, you might be wondering, “Why not just stick with traditional metals like steel or aluminum?” Well, here’s the thing: carbon fiber offers a unique combination of properties that traditional materials simply can’t match. Let’s break it down.

Key Advantages of Carbon Fiber Shafts

- Lightweight: Carbon fiber is significantly lighter than metals like steel and aluminum, making it perfect for applications where weight reduction is crucial.

- High Strength-to-Weight Ratio: Despite being lightweight, carbon fiber is incredibly strong. It can withstand heavy loads without compromising performance.

- Corrosion Resistance: Unlike metals, carbon fiber doesn’t rust or corrode, which makes it ideal for long-term use in harsh environments.

- Thermal Stability: Carbon fiber maintains its integrity even in extreme temperatures, ensuring consistent performance across a wide range of conditions.

- Versatility: Carbon fiber shafts can be customized to meet specific design requirements, whether you need a specific diameter, length, or finish.

In short, carbon fiber shafts are engineered to deliver superior performance without the bulk and weight of traditional materials. This makes them a top choice for industries ranging from aerospace to sports equipment manufacturing.

Applications of the Best Carbon Fiber Shafts

Now that we’ve covered the basics, let’s talk about where you’ll find carbon fiber shafts in action. These versatile components are used in a wide range of applications, each benefiting from their unique properties. Here are some of the most common uses:

1. Aerospace Industry

In the aerospace sector, weight is everything. Every gram counts when it comes to fuel efficiency and payload capacity. That’s why carbon fiber shafts are widely used in aircraft components, such as turbine blades, landing gear, and control systems. They help reduce overall weight while maintaining structural integrity.

2. Automotive Industry

From high-performance race cars to electric vehicles, carbon fiber shafts are increasingly being adopted in the automotive industry. Their lightweight nature improves fuel efficiency, while their strength ensures durability under demanding conditions.

3. Sports Equipment

Ever wondered why professional golfers and tennis players use carbon fiber equipment? It’s all about performance. Carbon fiber shafts are used in golf clubs, tennis rackets, and fishing rods to provide better control, increased power, and reduced fatigue for athletes.

Read also:Prince Harry And Meghan Markle Wedding A Look At The Massive Security Efforts

4. Industrial Machinery

In industrial settings, carbon fiber shafts are used in conveyor systems, robotics, and other machinery that requires precision and durability. Their resistance to wear and tear makes them a reliable choice for long-term use.

Factors to Consider When Choosing Carbon Fiber Shafts

Not all carbon fiber shafts are created equal. To ensure you’re getting the best product for your needs, there are several factors you should consider:

1. Material Quality

The quality of the carbon fiber material is crucial. Look for shafts made from high-grade carbon fiber with a low resin content. This ensures better mechanical properties and performance.

2. Manufacturing Process

The manufacturing process plays a significant role in determining the quality of a carbon fiber shaft. Look for manufacturers that use advanced techniques like filament winding or autoclave curing to produce high-quality products.

3. Customization Options

Depending on your application, you may need shafts with specific dimensions, finishes, or coatings. Choose a supplier that offers customization options to meet your exact requirements.

4. Price vs. Performance

While carbon fiber shafts can be expensive, it’s important to weigh the cost against the performance benefits they offer. In many cases, the long-term savings in weight reduction and maintenance make them a worthwhile investment.

Top Brands for Carbon Fiber Shafts

When it comes to choosing the best carbon fiber shafts, brand reputation matters. Here are some of the top brands you should consider:

1. Toray Industries

Toray is a global leader in carbon fiber production, known for its high-quality materials and innovative technologies. Their carbon fiber shafts are widely used in aerospace and automotive applications.

2. Hexcel

Hexcel specializes in composite materials, including carbon fiber shafts. Their products are renowned for their strength, durability, and versatility.

3. Zoltek

Zoltek offers cost-effective carbon fiber solutions without compromising on quality. Their shafts are popular in industries like wind energy and sports equipment.

How to Install Carbon Fiber Shafts

Installing carbon fiber shafts requires a bit of know-how to ensure they perform optimally. Here are some tips to help you get the job done right:

1. Preparing the Surface

Before installation, make sure the surface is clean and free of debris. This ensures proper adhesion and prevents damage to the shaft during assembly.

2. Alignment

Proper alignment is critical for optimal performance. Use precision tools to ensure the shaft is perfectly aligned with other components.

3. Torque Settings

Follow the manufacturer’s recommendations for torque settings to avoid over-tightening or under-tightening the shaft. This helps prevent damage and ensures longevity.

Common Misconceptions About Carbon Fiber Shafts

There are a few misconceptions about carbon fiber shafts that we need to clear up:

1. They’re Too Expensive

While carbon fiber shafts can be more expensive upfront, their long-term benefits often outweigh the initial cost. Consider the savings in weight reduction, maintenance, and performance improvement.

2. They’re Fragile

Carbon fiber is incredibly strong and durable. While it may not be as impact-resistant as metals, its strength-to-weight ratio makes it a superior choice for many applications.

Data and Statistics on Carbon Fiber Usage

Let’s back up our claims with some hard data. According to a report by Grand View Research, the global carbon fiber market is expected to grow at a CAGR of 11.2% from 2022 to 2030. This growth is driven by increasing demand in industries like aerospace, automotive, and renewable energy.

In the aerospace sector alone, carbon fiber composites account for over 50% of the materials used in modern aircraft. This trend is expected to continue as manufacturers seek ways to reduce weight and improve fuel efficiency.

Tips for Maintaining Carbon Fiber Shafts

Proper maintenance is key to maximizing the lifespan of your carbon fiber shafts. Here are some tips to keep them in top condition:

- Regularly inspect the shafts for signs of wear or damage.

- Clean the shafts with a mild solvent to remove dirt and debris.

- Store the shafts in a cool, dry place to prevent moisture damage.

- Follow the manufacturer’s guidelines for maintenance and repair.

Conclusion: Elevate Your Projects with the Best Carbon Fiber Shafts

And there you have it—a comprehensive guide to the best carbon fiber shafts and everything they can do for your projects. Whether you’re a professional engineer or a hobbyist looking to upgrade your gear, carbon fiber shafts offer unmatched performance and reliability. By considering factors like material quality, manufacturing process, and customization options, you can find the perfect shaft for your needs.

So what are you waiting for? Take the first step toward upgrading your projects today. Leave a comment below to share your thoughts, ask questions, or suggest topics for future articles. And don’t forget to check out our other guides for more insights and tips!

Table of Contents

- What Makes Carbon Fiber Shafts So Special?

- Applications of the Best Carbon Fiber Shafts

- Factors to Consider When Choosing Carbon Fiber Shafts

- Top Brands for Carbon Fiber Shafts

- How to Install Carbon Fiber Shafts

- Common Misconceptions About Carbon Fiber Shafts

- Data and Statistics on Carbon Fiber Usage

- Tips for Maintaining Carbon Fiber Shafts

- Conclusion